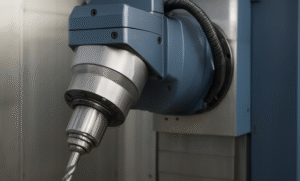

What is a Winkelbohrspindel?

The winkelbohrspindel, commonly referred to as an angular drilling spindle, is a sophisticated tool used in various machining processes to enhance precision and efficiency. Defined by its unique ability to drill at various angles, the winkelbohrspindel is equipped with a set of key components that include a spindle motor, a drilling bit, and an adjustable head that allows for the desired angling. This design enables machinists to create holes that are not strictly vertical or horizontal, accommodating a range of application requirements.

In industries such as woodworking, metalworking, and construction, the winkelbohrspindel plays a pivotal role. For instance, in woodworking, it is utilized to create intricate joinery and complex angles that are essential for furniture and cabinet making. Similarly, in metalworking, the interactivity of the winkelbohrspindel with different metals allows for precise drilling that meets high-quality standards. Furthermore, in the construction sector, this tool assists in installing components that demand accurate angular placement to ensure structural integrity.

The operational mechanism of the winkelbohrspindel is designed to deliver high torque and stability, making it ideal for both heavy and delicate materials. When machining, the user can adjust the angle of the spindle according to the specifications of the project, which leads to enhanced flexibility in design and execution. The versatility of this tool also extends to its compatibility with various types of drill bits and attachments, further amplifying its utility across different sectors.

In essence, the winkelbohrspindel is indispensable to modern machining practices, combining art and science to facilitate precision in tasks that require meticulous attention to detail. Its role in bolstering productivity and ensuring accuracy cannot be overstated, establishing it as a cornerstone in contemporary manufacturing environments.

Advantages of Using a Winkelbohrspindel

The winkelbohrspindel stands out in various operational contexts, offering numerous advantages that enhance drilling efficiency and precision. One of the most prominent benefits is the significant improvement in accuracy. The design of the winkelbohrspindel allows for precise control over the drilling angle and depth, which is crucial in applications requiring exact specifications. For instance, manufacturers using this tool can achieve consistent results, reducing the risk of deviations that could lead to costly errors.

Time savings constitute another compelling advantage of the winkelbohrspindel. Traditional drilling methods often involve a series of manual adjustments and recalibrations, consuming valuable time in high-stakes production environments. The winkelbohrspindel, however, streamlines the process by enabling quicker setup and adjustments, translating to faster completion of projects. This efficiency is particularly beneficial in sectors such as automotive or aerospace, where time-to-market is critical.

Flexibility in drilling operations is yet another key advantage of utilizing a winkelbohrspindel. Its capability to operate at various angles makes it ideal for complex drilling tasks, as it can adapt to different workpieces without requiring significant modifications or downtime. For example, when executing intricate patterns or holes in custom fabrication projects, the winkelbohrspindel enables operators to navigate challenging geometries seamlessly.

Real-world examples abound where the winkelbohrspindel outperforms conventional drilling tools. In construction, for instance, contractors report reduced drilling times and enhanced accuracy when utilizing winkelbohrspindeln for foundation work. Such operational improvements highlight the strategic advantages of incorporating this specialized equipment into various workflows. Ultimately, investing in a winkelbohrspindel not only bolsters productivity but also enhances the overall quality of the output, proving that this tool is indispensable in modern drilling practices.

Choosing the Right Winkelbohrspindel for Your Needs

Selecting the appropriate winkelbohrspindel is a critical decision that can significantly impact your machining capabilities and overall operational efficiency. When considering a winkelbohrspindel, several factors must be taken into account to ensure it meets your specific requirements. Firstly, assess the size and compatibility of the winkelbohrspindel with your existing machinery. It is vital that the spindle fits well within your current setup to avoid performance issues and unnecessary adjustments that can lead to downtime.

Moreover, different applications demand varying features from a winkelbohrspindel. For instance, those participating in fine detail work may prioritize spindles with higher precision and finer adjustments, while industries involved in high-volume production may require robust models that are durable and capable of sustaining rigorous use. It is advisable to consider the rotational speed, torque capabilities, and the range of materials that the spindle can effectively work with. Additionally, think about whether you need a fixed or adjustable spindle based on your operational needs.

Evaluating suppliers is also an essential part of the selection process. Look for reputable manufacturers with a proven track record in the industry. Consider customer reviews, product warranties, and after-sale support when making your choice. Popular models on the market often come from well-known manufacturers recognized for their quality and reliability. These products typically combine innovation with functionality, ensuring they can handle a wide range of machining operations with precision. By taking the time to research and compare different winkelbohrspindels, along with consulting experienced professionals in the field, you can acquire a spindle that not only meets your expectations but also enhances your overall productivity.

Maintenance and Best Practices for Winkelbohrspindels

Proper maintenance of winkelbohrspindels is crucial for ensuring their longevity and performance. Regular cleaning is one of the foundational practices that users should adopt. Dust, debris, and metal shavings can accumulate during operation, leading to potential wear and tear. To clean the spindle, ensure it is powered off, then use a soft brush or lint-free cloth to remove any buildup. For deeper cleaning, consult the manufacturer’s manual for specific instructions, as some components might require disassembly for thorough maintenance.

Lubrication is another essential aspect of maintaining a winkelbohrspindel. Using the right type of lubricant is vital – always refer to the manufacturer’s guidelines for recommended products. Apply lubricant at the designated intervals to all moving parts, as this reduces friction and prolongs the life of the tool. An adequately lubricated spindle not only enhances performance but also minimizes the risk of overheating and mechanical failure.

While operating winkelbohrspindels, it is important to recognize and troubleshoot common issues. Some typical problems might include unusual noises, overheating, or a decrease in accuracy. If any irregularities occur, stop using the tool immediately and conduct an inspection. Many issues can often be resolved by simply cleaning or lubricating the device, or by checking for misalignments. If the problem persists, contacting a qualified technician may be necessary.

Finally, adhering to safety guidelines is paramount when using winkelbohrspindels. Always wear appropriate personal protective equipment, such as goggles and gloves, to protect against flying debris. Familiarize yourself with the operation manual, particularly safety alerts and risk factors, to ensure a safe working environment. By implementing these maintenance tips and best practices, users can enhance the efficiency and durability of their winkelbohrspindel, facilitating superior performance in precision tasks.